Thinking of Upgrading to a Pallet Wrapping Machine?

Are your hand held wrap dispenser systems not keeping up with demand and you are thinking of upgrading to a pallet wrapping machine? Stretch wrapping is the most popular way to secure a pallet load for shipping. Millions of pallets get wrapped every single day. Stretch wrap is strong enough to be stretched tight, is puncture and tear resistant, keeping the pallet load safe intact during transit.

The most efficient method of dispensing stretch wrap is via a purpose-built machine. Stretch wrap such as Orbitwrap Save uses the latest in plastic technology to make a more efficient product with less waste that is 100% recyclable. A stretch wrap machine can get more distance out of a roll of wrapping material than a handheld dispenser.

There are manual, semi-automatic and fully automated pallet wrapping solutions. Depending on your production output there are things you to consider when deciding on whether you need to go to the expense of purchasing a stretch wrap machine.

You need to ask yourself how would your business benefit from purchasing a stretch wrapping machine, would it be more efficient to go semi-automated or fully automated? How many pallets do you wrap per year? How much stretch wrap do you use per year and could a machine help reduce those costs significantly? How much manual labour do you use for pallet wrapping and could the cost of a machine eventually pay for itself in a reasonable amount of time?

Manual Pallet Wrapping Solutions

A manual dispenser has a roll of stretch wrap mounted on the tool plus hand grips and the pallet is wrapped by a worker who walks around the pallet keeping the wrap as tight as possible during the application.

Compared to thousands of dollars a premium handheld stretch wrap dispenser will cost you under $200. A manual stretch wrapping solution also equals the cost of manual labour, the possibility of back injury and carpal tunnel which would include sick pay and the cost of a replacement worker. There would also be the expense of using more wrapping material due to the inability of manually dispensed stretch wrap to be as efficient as a machine.

Upgrading to a Pallet Wrapping Machine

So now you have worked out that you need a pallet wrapping machine for efficiency in your production line what type of machine do you need? This is where you would consider whether you should invest in a manual, a semi-automatic or fully automated stretch wrapper machine.

A fully automated wrapping machine does the complete job of placing the pallet in the wrap zone, wrapping it according to pre-determined settings. When completed, the pallet is sent down the conveyor to the end of the production line while the next pallet is already in place to repeat the process.

Both manual and semi-automated wrapping machines require some form of manual labour, whether it is loading the pallet to the wrap zone by forklift, adjusting the controls and unloading the pallet when the wrapping is complete.

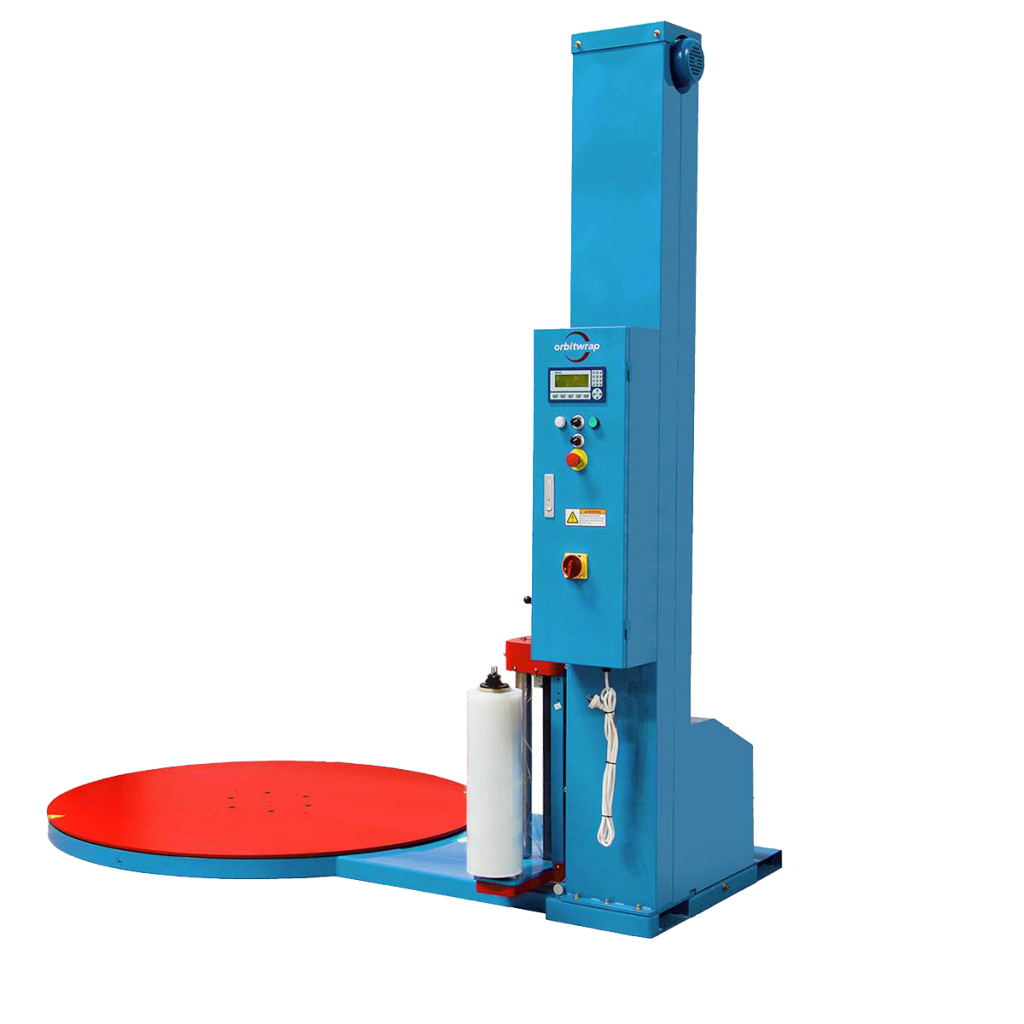

Turntable Wrapper Machine

A pallet is placed on the machine’s turntable and the stretch wrap is applied when the turntable spins, applying the stretch wrap from the bottom to the top and back down again. These machines are a good choice for small companies and for companies with a high production rate. These machines can provide savings in wrap wastage and labour intensity.

Horizontal Orbital Wrapper

The Horizontal orbital wrapper is a speedy machine that wraps a pallet horizontally by going under and over the load while moving down a conveyor. These machines are used to wrap oddly shaped items or longer loads that cannot be stacked at height or evenly in cartons.

Practical Steps before you buy

Back to the questions posed earlier in the article, before you go ahead and buy a machine there are some practical steps you can take to ensure you are going to purchase the right machine for your business. Once you have taken the following steps you can contact a stretch wrap expert to help you with an analysis of your pallet wrapping system to work out the most efficient upgrade for you.

#1 Take an inventory

The first step would be to take an inventory of the number of pallets you wrap in a month and how much stretch wrap you use to secure these pallets. Once you have completed this analysis it will give you a report on how much wrap you use and the cost annually.

#2 Labour

Work out the cost of labour, the time taken to manually wrap pallets over a month, the loss of production due to staff morale related to repetitive manual labour. Also, if you have had staff absences due to workplace injury, the cost of replacement staff and any other related expense.

#3 Product loss and damage

Have you had losses due to poorly wrapped pallets where goods have been damaged or fallen off the pallet during transit? Have you had to cover those losses?

#4 Your budget

Investing in a pallet wrapping machine is going to cost you a lot. Having your production line analysis completed and after advice from your Packaging Supplier you can decide whether an investment in a pallet wrapper is of benefit to your company.

#5 Research the brand

Once you have concluded that you need to upgrade, its time to research the different brands available. There are many brands of machine out there, so the easiest way is to pick a few and research them from there.

Cost is a big factor but also look at customer reviews, focus on the quality brands and whether they are serviceable, and you can get replacement parts. Ask your Packaging Supplier about after purchase customer care.

A lot of these machines cannot be bought direct from companies who wholesale their own brands. You will often have to go through a Packaging Supplier who will have multiple brands to choose from. This is a good thing, as the Packaging Supplier will be able to tell you which brands popular and which machines get less repair enquiries and which machine will do the right job for you.

Conclusion

Once you have identified that your organisation has the need for upgrading to a pallet wrapping machine it is important that your staff are trained on your new machine’s safe and efficient operation. Once pallet wrapping machine is running at full capacity you will see an increase in production coinciding with less labour and materials cost.

See some of our Pallet Wrapping Machine Range here: